Ensuring quality in the electronics industry presents a complex challenge for quality management professionals. Stringent compliance regulations, the potential for costly product recalls, and ever-evolving customer demands necessitate a robust quality management system (QMS) that emphasizes continuous improvement and risk mitigation.

Quality Challenges in Electronics Manufacturing

It’s a brutal marketplace if you sell consumer electronics, semiconductors, home appliances, telecom equipment, or similar products. That’s not only due to the fierce competition, each trying to get a piece of the revenue pie, but also the supply chain hurdles you must overcome to produce top-quality electronics.

Internal and External Quality Pressures

Maintaining quality for your electronics isn’t as easy as evaluating inventory and checking an “Approved” box. Numerous operational complexities stand in the way of simple quality management:

- Intricate supply chains: You rely on a lot of different materials (metals, silicon, plastics, ceramics, composites, etc.) from various suppliers spread all over the world.

- Complex product design: Electronics have many moving parts and technical components that require high precision during manufacturing.

- Rapid technology innovation: New materials and manufacturing tools emerge every year and get adopted into production lines, forcing you to adjust quality control practices.

And it doesn’t end there. Market-driven forces on the outside have added more headaches to a quality professional’s day-to-day. Material costs, for example, have risen substantially over the last few years — with a 9.9% spike in 2023. Combine this with a 9.2% labor cost increase and a 7.2% boost in freight costs, and it’s becoming harder and harder to get production lines adequate resources for sound quality assurance.

Impact of Global Market Demands

The electronics manufacturing industry is booming, with a compound annual growth rate (CAGR) forecast of 4.8% over the next half-decade. That translates to ambitious production quotas to meet surging customer demand. Labor and resource shortages hinder efforts to meet these goals, raising concerns about quality as manufacturers push to increase production.

Separately, as production scales to serve global demand, electronics manufacturers will have their work cut out for them when it comes to compliance. More facilities spread globally means adopting controls for standards like ISO 9001 and Restriction of Hazardous Substances (RoHS) — and that doesn’t even include regional consumer and regulatory requirements that vary by country.

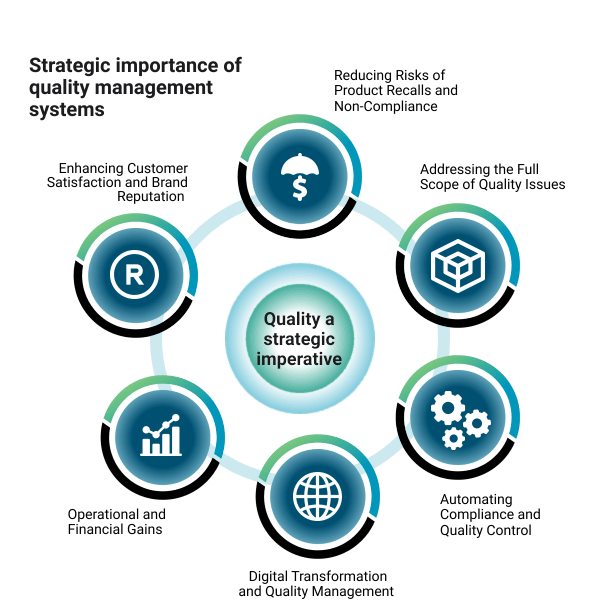

Strategic Importance of Quality Management Systems

The cost of poor quality (COPQ) is cutting your profits. And even just one bad incident can change the public perception of your brand forever. That’s why an eQMS isn’t just a nice-to-have for electronics companies but a strategic imperative.

1. Reducing Risks of Product Recalls and Non-Compliance

2023 was a big year for U.S. product recalls — with over 759 million units removed from the shelves, with the second most being electronics and home appliances. Recalls are as common as they are expensive. The average incident can cost an electronics company $12 million on average.

You don’t want to fail to meet ISO 9001 compliance, RoHS, and other safety standards, which could ultimately result in a recall. Between non-compliance penalties, regulatory fines, legal fees, and the cost of corrective and preventive actions (CAPA), investing in a robust QMS is far less expensive than the COPQ.

2. Addressing the Full Scope of Quality Issues

The immediate financial impact of a quality incident is just the tip of the iceberg. Beyond a product recall, there are plenty of other considerations for which lackluster quality management gets in the way of your success:

- Customer churn from poor-quality electronics: Leads to lost business down the road and reduced market share

- Negative brand perception: Damages relationships with suppliers and customers while creating distrust from investors

- Incidents can cause production delays for corrective actions: Extends the new production introduction (NPI) lifecycle.

Luckily, quality automation can be your lifeline to reducing these issues.

The Role of Automation in Quality Management

Quality automation through an integrated QMS is the key to enterprise success in the electrical manufacturing industry. Here’s how:

3. Automating Compliance and Quality Control

Have you ever wanted to standardize electronics production across multiple facilities? Maybe you just went through an M&A or are scaling faster than expected and need to ensure consistent quality in what you produce: The same materials, processes, documentation, etc.

Well, that’s precisely what automation through a QMS does. This system can manage all your documents, employee training, audits, correction actions, and suppliers. That way, all your electronics, no matter where produced, meet the same high-quality and compliance standards.

When you make any production changes or need to implement new quality controls, every facility across the world is notified and can access the necessary documentation to “fall in line.” A QMS even supports global harmonization — helping navigate international standards and incorporate practices for unique regional regulatory requirements. Super helpful when launching into new global markets and trying to foster customer trust worldwide.

4. Digital Transformation and Quality Management

Historically, manufacturing companies have operated out of outdated facilities using older technology. Now, there’s a nuanced pressure to digitally transform with modern tech stacks. Investing in a QMS is an excellent start to modernizing and automating quality management — offering features like:

- Real-time production monitoring with actionable insights for faster decision-making and immediate quality control adjustments

- Collaboration tools for quality teams to communicate, provide updates, edit documents, and obtain signatures for approval

- Centralized portal for production, supplier, quality, SOPs, and material data to help make more informed decisions

It’s time to evolve past spreadsheets, emails, and posted notes. That’s no way to manage the quality of your electronics. It’s slow, unreliable, and puts you at a higher risk of quality errors. Instead, try a QMS: The massive efficiency hack you’ve been looking for to automate quality.

Key Benefits of Implementing Advanced QMS

The foundation of business growth is producing quality electronics. Here’s how an advanced QMS lets you “win” at manufacturing and quality control:

5. Operational and Financial Gains

Vital for a rapidly growing market, a QMS powers up production and lets you easily scale electronics production:

- It’s easier to standardize and harmonize production across multiple global locations.

- You get more quality consistency in electronics design, functionality, and safety.

- Quality processes get completed faster to speed up NPI times.

- Centralized audits and risk assessments make compliance a breeze.

A QMS also improves your bottom line. Imagine avoiding non-compliance fines, product recall costs, CAPA expenses, and other COPQs that diminish profits. It even helps you scale production more efficiently and cut down on the cost of goods sold (COGS) without compromising electronics safety or performance.

6. Enhancing Customer Satisfaction and Brand Reputation

The benefits of QMS ultimately trickle down to the customer. Automating quality lets you create safe and highly functional electronics across all your facilities that:

- Exceed customer expectations across different regions or countries

- Avoid product recalls

- Meet safety and compliance standards around the world

What does this mean for your brand? A reputation for quality that builds trust and customer relationships lasting a lifetime.