Comparing the cost of good and bad quality

Many organizations might see quality as an expense that is a necessary evil, especially when they have proactive processes in place to avoid nonconformance. But the reality is that there’s a big difference between the costs of good quality and the costs associated with handling and fixing poor quality products. What is the Cost of Poor Quality?

The economic framework of quality

There are many costs associated with quality. Organizations must invest in their processes, implement a quality management system, and shoulder any costs associated with activities such as inspection and testing to achieve high‑quality products. This all works to prevent low‑quality products.

While this might seem like a significant outlay, it’s considerably less than the cost of poor quality. With poor‑quality products, organizations will see costs increase in areas like scrap and rework, warranty claims, regulatory fines, and more.

The cost of good quality (COGQ) is important to consider for any organization and is a worthy outlay when compared with the cost of poor quality (COPQ).

Costs of good quality

The cost of good quality is important for all manufacturers as it ultimately saves money by avoiding the costs of poor quality.

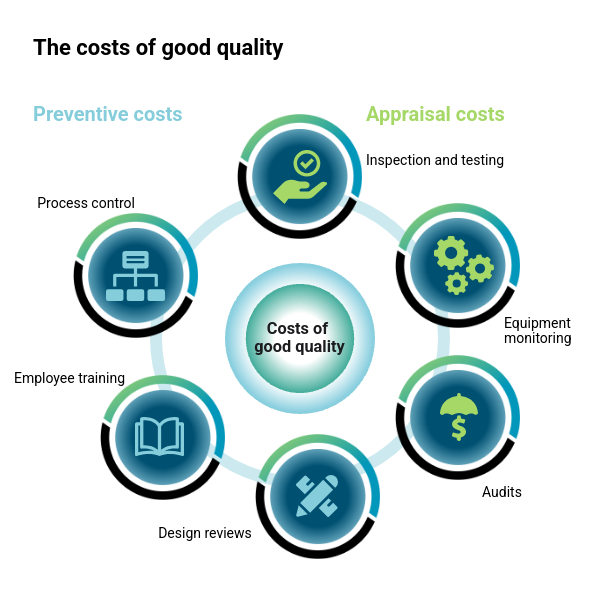

Prevention costs

Prevention costs are those that protect against poor quality. These include:

- Process control

This enables an organization to carry out manufacturing processes efficiently with as little variation as possible. It helps improve safety, save energy, and maintain quality — often using technology such as thermostats, sensors, and infrared cameras linked to a quality management system. - Employee training

Keeping employees updated with current quality processes is important as this helps with

productivity, consistency, and document control. - Design reviews

Reviews should take place to establish how

a design adheres to requirements and what might need extra attention during manufacturing.

Appraisal costs

These costs are associated with quality control during or after a product has been manufactured. These activities include:

- Inspection and testing

This is to test whether the product meets industry and quality standards but could extend to testing individual materials. - Equipment monitoring

Many quality standards (such as ISO 9001) require equipment monitoring to ensure it is safe, up‑to‑date, and working properly. - Audits

A manufacturer may need to undertake a range of audits, from self‑inspections to third‑party audits for certification.

The purpose of prevention and appraisal costs is to avoid the negative effects of poor quality. While this may be seen as a cost center, businesses should understand it’s a necessary part of manufacturing that helps prevent future issues and associated costs.

Costs of poor quality

While some of the costs of poor quality might be obvious, the impact of ongoing nonconformances and failures goes far beyond the need to rework a product.

Internal failure costs

These are costs to correct an issue discovered before the product reaches the customer. They include:

- Scrap and rework

Anything from ordering the wrong parts to poor execution of a design can cause these issues. These expenses add

up quickly while also wasting time and materials. - Productivity

Whether caused by planned downtime, injuries, illness, or equipment failure, when productivity takes a hit, it impacts an organization’s bottom line. - Material replacement

Poorly managed materials can lead to delays, increased rework, and

the additional costs of replacing materials that don’t meet quality standards.

External failure costs

These are the costs incurred after a faulty or poor-quality product reaches the customer. Typically, they cost five times more to fix than internal failures.

- Customer complaint handling

Mitigating some of the ongoing issues associated with poor quality involves listening to and handling customer complaints. Doing so helps fight any fires while also gaining a better understanding of where the quality issues might be coming from. - Warranty claims

These are the expenses an organization incurs when a purchased item is repaired or replaced under warranty. This can soon add up if products go to customers without proper quality control or processes. - Return costs

An unsatisfied customer triggers a series of events beyond the cost of return postage, from warehousing requirements to scrap to labor costs. - Regulatory fines and penalties

Proper quality processes make compliance significantly less expensive than non-compliance. A faulty product could lead to fines and penalties from governing bodies.

Addressing less tangible costs

While it’s possible to put a figure on the costs associated with rework, regulatory fines, and warranty claims, there are fewer tangible costs that, while harder to measure, still impact a business and its ability to make money.

- Brand damage

If a brand becomes known for poor-quality products, this can negatively affect sales and cause customers to choose a competitor instead. Damage to the brand could also impact supply chain relationships and other partnerships. - Loss of customers

As well as losing existing customers, a reputation for poor quality could also result in a drop in new customers.

The costs of poor quality can soon stack up, but let’s dig deeper into what the costs of good quality look like and what the return on investment (ROI) might be.

Cost of quality and return on investment

While the cost of quality will vary between companies, there’s a simple calculation to help determine a business’s overall cost of quality.

COQ = COGQ (cost of good quality) + COPQ (cost of poor quality)

The American Society for Quality says that COPQ can range anywhere from 10 to 20 percent of a company’s revenue. This means that a company with $100 million in annual revenue could be spending $20 million on the costs of poor quality.

Reducing the COPQ will put money back into the company’s bottom line — approximately $1 million annually per percentage point COPQ reduction

based on the above example.

Variability in COQ across companies

Investing in quality might increase the overall COGC but will also bring down the COPQ. This is an important consideration when looking at the ROI of a quality management system, but there’s huge variability in the COQ across companies.

Take General Motors, for example. It has previously tracked certain processes in its manufacturing plants with paper-based processes, physical signatures, and consultants working long hours. Automating these processes with a quality management system saved $165,000 (85% of its initial budget for improving its quality processes) in a single decommissioning process. In addition to these savings, quality automation helped GM save a further $1 million in scrap revenue.

Improving a single process may have increased the cost of quality, but the savings against the cost of poor quality are significant. These costs are variable. However, with those in heavily regulated sectors, such as the medical device industry, the cost of quality might be higher.

For example, larger organizations looking to meet industry standards might proactively hire an ISO consultant costing around $20,000 to $30,000. While that might seem like a hefty outlay to some, there are huge potential savings from being proactive.

Trane Technologies took proactive steps to improve its quality management and implemented ETQ Reliance®, bringing more automation into its processes. Not only did it reduce warranty costs by 70 percent — saving millions of dollars — it also managed to reduce scrap and rework by 32 percent.

Reduction strategies

In order to reduce the cost of quality, it’s important to look at the prevention strategies that will reduce COPQ.

For example, Six Sigma is a set of management techniques designed to reduce the likelihood of errors

and defects. It’s possible for companies who have achieved Six Sigma to reduce the COPQ to lower than one percent of total revenue.

While this might increase the cost of quality, dropping COPQ could mean a significant return on investment.

On top of reducing the tangible costs of poor quality, there are additional benefits to a proactive approach.

Becoming known as a company that consistently produces high-quality products can lead to a positive perception of the brand that leads to increased customer loyalty and overall revenue.

The business case for quality investment

It’s quite clear there’s a business case for quality investment that prioritizes a proactive approach to quality management, but there can be challenges associated with this change in mindset.

Often, both employee and leadership resistance to change can halt a quality initiative. It’s crucial to address these objections and those around budget constraints, the need for training and development, and measuring ROI. It’s important to highlight the risks of not investing in quality, and budget concerns often come down to a simple question of, “Can we afford not to do this?”

To develop a convincing argument for quality improvement, quality managers should tackle these three key areas:

- Financial

An organization’s financial team will want to see the potential ROI, so it’s vital to highlight COPQ and how reducing this could lead to savings. - Legal

The legal implications of poor-quality products are far-reaching, and this goes beyond the fines associated with non-compliance, as faulty products could lead to legal action, especially in highly regulated and safety-critical industries. - Organizational

While there may be some hurdles to overcome, an organization will be stronger for having clear quality management processes in place. This will not only improve productivity but can also improve safety in the workplace.

Importance of investing in quality

Investing in quality has a ripple effect across all areas of the organization, no matter its size or

the industry in which it operates. From clear, tangible savings to improved brand reputation leading to more customers, this is a necessary step for any business serious about its future.

It’s down to quality managers to advocate for this investment by clearly communicating the need for proactive processes that help reduce COPQ, foster a safer working environment, and free up employees to be more productive through the automation of certain tasks.

With ETQ Reliance, customers have shown measurable improvement in reducing their cost of poor quality.

- Kimberly Clark’s solution for two-way supplier collaboration delivered a 3,200% ROI through the elimination of unnecessary software, manual work and business risk.

- Lumileds has cut its QMS technology footprint by 35% and trimmed about $700,000 per year in operating costs for QMS.

- Trane reduced scrap and rework by 32% & reduced overall warranty costs by 70% & tens of millions of dollars

- Wabtec saw $30M in annual savings in cost of quality programs. Cut the cost of poor quality by 15%, including a 50% reduction in tooling costs. Added $10-$12M in productivity gains over the last decade.

- United Airlines saves $120,000 in future damage costs with ETQ Reliance Safety Management.