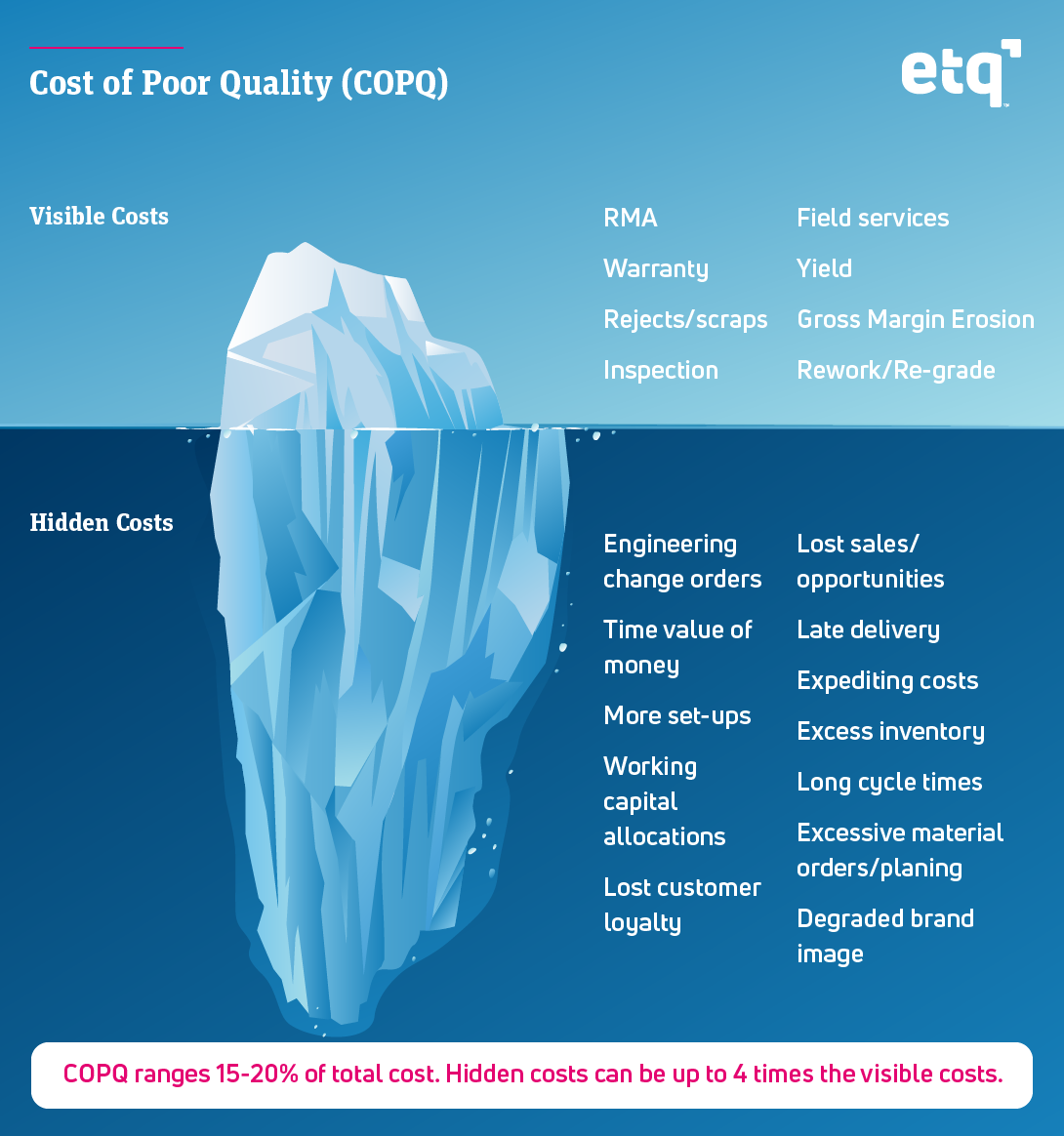

Most companies are well acquainted with the “visible” costs of poor quality, both internal and external. But these are just the tip of the iceberg compared to the deeper and more intractable “invisible” costs lurking below the waterline. These costs incurred are often associated with quality control and assurance. It behooves companies that value quality leadership and high standards to fully understand and account for these hidden costs or risk losing consumer trust, brand reputation and, ultimately, business value.

Companies that think of quality as only a cost center enforce the incorrect perception that the quality function is essentially a thumbs up or the bearer of bad news. As we’ll see, by embracing a comprehensive view of quality management, companies can limit the visible and hidden impacts of poor quality and use quality management as a true business optimization tool.

Calculating the true cost of quality

The true cost of quality is hard to quantify. In fact, the visible costs of poor quality, or COPQ, are just the tip of the iceberg. The easy-to-see and easy-to-measure parts like inspection defects and internal failure rates are the main categories that provide the metrics and data, but it is the less obvious costs that can have the biggest impact on quality.

To continue the COPQ iceberg analogy, the hidden costs below the waterline are the ones that drive up the total cost of bad quality. Engineering change orders, noncomformances, customer complaints, lost sales, late delivery, product re-works, supplier incapability, excessive raw material orders, long cycle times, working capital allocations, degraded brand image, lost customer loyalty… these nested costs are a laundry list of failures that are the major contributors to the cost of poor quality.

This concept is nothing new. In fact, the topic was discussed extensively at a recent LNS Research-hosted industrial transformation event with quality executives from a variety of industries that I was fortunate to be a part of.

Commonly referred to as the “hidden factory” by economists and quality professionals, these costs are more incremental in nature and come into play when a drifting or “out of control” manufacturing process decreases both the quality and efficiency of a production line. In a perfect world with unlimited time, all defects would be identified, removed from the production line, fixed and placed back on the line. Sadly, we don’t live in a perfect world.

One of the more defining characteristics of the hidden factory is that the longer that problems exist, the higher the associated costs. There is a consensus that the COPQ can be 10 to 15 percent of operations and hidden costs can be as much as four times the visible costs. In fact, noted quality guru Armand Feignbaum believed that every American company had hidden factory operating costs that ranged from anywhere between 20- to 40 percent of total capacity. If that is the case, then it is obvious that the costs that lie beneath the surface are draining a significant amount of working capital.

In a traditional manufacturing scenario – one in which a company has yet to automate its quality management process and relies on both the outmoded image of quality as the “bad cop” and archaic working practices – nonconformances or other quality problems risk being lost in a series of disconnected systems.

As a result, corrective actions are delayed, if implemented at all, and the consequences beyond the obvious “above the waterline” issues are well hidden in the short-term. Over time, the “below the waterline” issues will have an even greater negative impact and require longer, more complex and costlier fixes than had the issues been resolved in near real time.

Recognizing the quality bottlenecks

Tempting as it is to believe that the siloed approach to traditional defect handling is an anomaly in the manufacturing industry, the fact is that this type of quality pain point happens on a regular basis and impacts the bottom line.

Expecting a corrective action ticket to be dealt with in seconds is unrealistic, but the failure to address the problem costs the company time, materials, money and, ultimately, a loss of customer satisfaction. In addition, the quality management team is blamed for not responding quickly enough or overreacting which leads to them being labeled as a bad actor by the rest of the company.

However, the quality function is typically not the problem. Instead, there is a need for the other business functions in the company to recognize that the bottlenecks in the system have prevented the issue from being fixed in a reasonable timeframe and contributed to the less obvious costs of quality.

Quality is often disconnected from the rest of the company, and there is still a perception that quality is a cost center as opposed to a business optimization or operational efficiency tool. When a problem occurs, the quality department often has to take part in an internal game of “whack-a-mole,” spending its time chasing quality-related issues that are – by and large – preventable.

The relevant support from IT or management is often lacking, and full integration with other business processes is not always achievable, especially in companies that still rely on paper-based processes and spreadsheets. Factor into the mix that business needs and customer demands are in a constant flux, and it becomes clear that the cost of poor quality is less dependent on the visible costs and more related to the dangers that lurk beneath the surface.

Effective implementation of quality tools must be done right

So, how do we solve these demonstrated pain points? The obvious answer would be to increase investment in prevention costs like quality management systems that can identify and fix corrective action notifications with a minimum of fuss. However, that is only part of the solution.

Quality management needs to be done right from day one. As we have said before, the quality department is an integral part of the product lifecycle. These are also the people working on the quality frontline and are responsible for time-tested tools that drive reliability. As a result, the overarching goal for any company that wants to cement its reputation as a quality leader is to maintain not only a focus on continuous improvement but also a culture of quality throughout.

Integrating a Plan-Do-Check-Act procedure should be a minimum requirement for any company that is serious about changing its attitude to change. This integration must incorporate a complete corrective action process (that includes a purposeful problem statement), in-depth root cause analysis, an appropriately scoped action plan and an effectiveness check.

In addition, quality leaders must manage change in a coordinated way. These actions include keeping procedures and work instructions up to date, ensuring ongoing compliance with workforce training requirements and defining the required scope and frequency for quality audits. All of these pathways to continuous process improvement are the basic platform on which seemingly complex quality problems can be solved.

Doing these things right will drive the quality culture across the organization and impact all the hidden issues as well the more visible ones. As an added bonus, it ensures that quality becomes everyone’s business … and not just the “bad cops” that prevent products or projects from moving forward.

Ultimately, a culture of quality must be instilled from the top down, and management must remove the notion that quality management is solely the bearer of bad news.

We live in a connected society where the fulfillment of customer expectations remains the benchmark for success, and quality plays a major role in meeting these expectations. Quality has always mattered. What is important now is that decision makers not only give it the recognition it deserves, but also close the doors that lead to the hidden factory.

ETQ‘s mantra is that quality creates endless possibilities, and we believe that competitive advantage grows when companies take an agile approach to quality management. These are some of the many reasons why over 550 global companies trust us to secure brand reputation and customer loyalty. Our Reliance SaaS software delivers built-in best practices and powerful flexibility to drive excellence through quality.

Find out more about how ETQ can help you on your quality journey.