What is Job Hazard Analysis?

A Job Hazard Analysis (JHA), is a process used to identify potential hazards associated with specific job tasks. This proactive approach is critical in preventing accidents and ensuring compliance with safety regulations.The

Occupational Safety and Health Administration (OSHA) mandates formal hazard analysis in certain situations. This requirement is necessary for tasks like confined space work or when a job requires Personal Protective Equipment (PPE). Conducting a Job Hazard Analysis (JHA) is one way to meet these requirements and make dangerous jobs less risky.

Conducting and writing a job hazard analysis involves breaking down jobs into tasks, determining the associated hazards, and implementing safety measures to mitigate those risks. A JHA helps manage workplace hazards in several ways:

- Identifies hazards before they cause accidents or injuries.

- Prevents hazardous conditions by identifying risks and developing controls.

- Ensures compliance with safety standards and regulations, reducing violations.

- Improves communication between employees and management about potential safety issues.

- Reduces absenteeism and turnover by creating a safe workplace, resulting in increased productivity and morale.

- Improves reputation as a safe and responsible employer and manufacturer.

Often used synonymously with JHA, a Job Safety Analysis (JSA) is also a systematic process used to identify potential hazards in the workplace and establish safe procedures for completing specific tasks. While job safety analysis and job hazard analysis are often used interchangeably, some organizations distinguish between them, with job safety analysis focusing more on safety procedures and job hazard analysis on identifying hazards.

Ultimately, both approaches aim to mitigate risks and enhance safety. The choice of term depends on your organization’s safety programs, but the goal is always to prioritize hazard prevention and foster a strong safety culture.

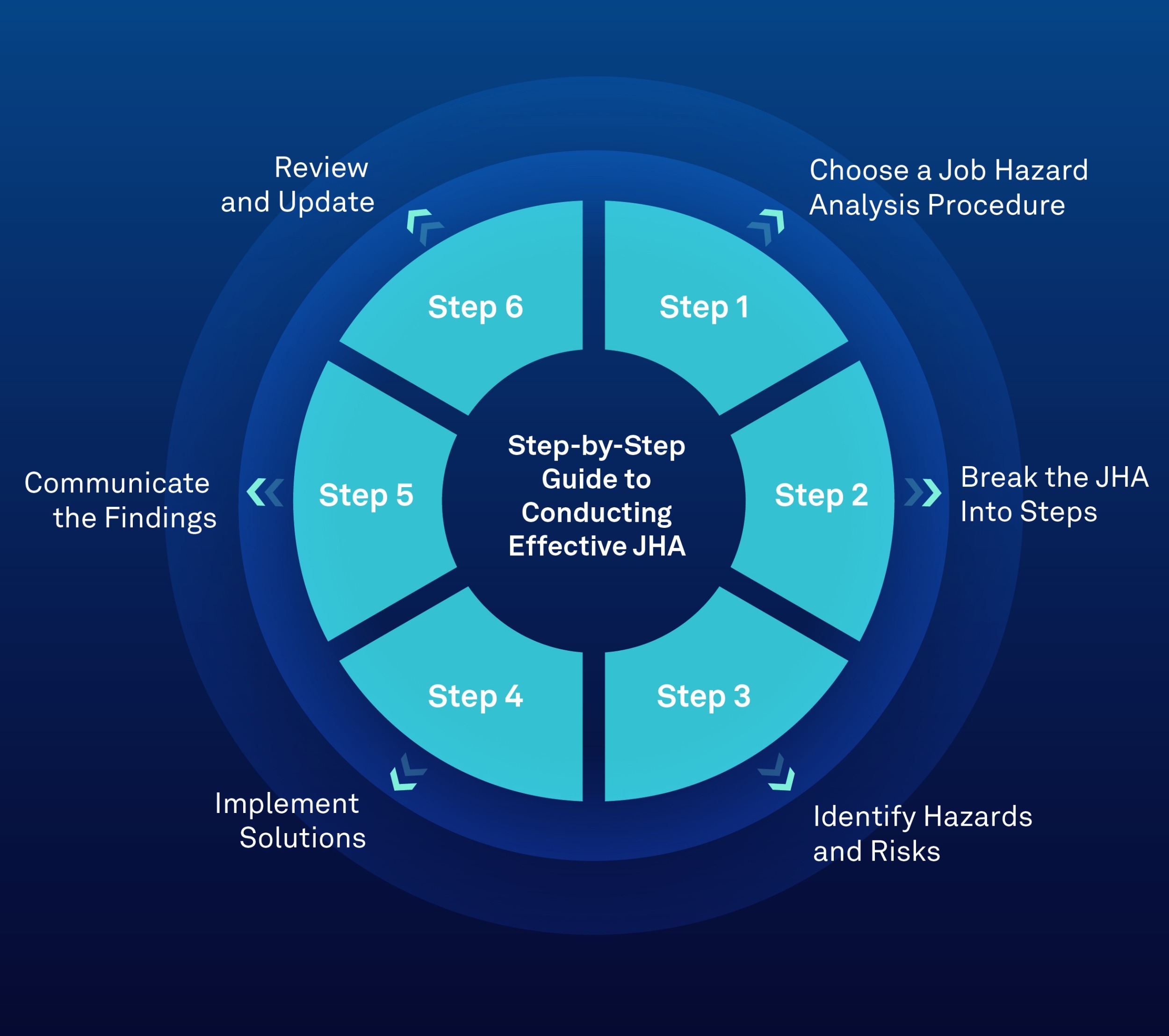

Step-by-Step Guide to Conducting Effective Job Hazard Analysis

Now that you understand what JHA and JSA mean, here are six simple job hazard analysis steps to guide you through the process.

Step 1: Choose a Job Hazard Analysis Procedure

The first step in performing a JSA is identifying where to focus. High-priority areas include procedures with:

- A history of past injuries or a high frequency of safety incidents

- High potential to cause an injury

- Potential for a high severity of incidents

- Infrequent use and low hazard awareness

- New processes or equipment, including recently changed processes

Refer to prior audits, risk assessments, and critical issues as a starting point for known hazards.

Step 2: Break the Job Hazard Analysis Into Steps

Take that job procedure under analysis and break it into manageable chunks or steps. The best way to do this is to observe employees while they do the job.

You don’t want it to be so general that you’re omitting key steps but not so granular that you have too many steps. The general rule of thumb is ten or fewer steps.

Step 3: Identify Hazards and Risks

At this point, you need to look at each step and pinpoint what could go wrong.

- Do moving objects or equipment pieces pose a hazard?

- Could necessary lifting, pushing, or pulling cause strain?

- Could the employee slip, trip, or fall?

- Are there environmental hazards like extreme temperatures, lighting, or noise?

- Are harmful substances such as chemicals, dust, or fumes involved?

Leveraging risk management software makes this step even more effective. Assess the risk of the procedure as a whole and at individual steps to determine where to focus on controls

To understand more about leveraging risk management software for JHA, consult with a quality management expert today.

Step 4: Implement Solutions

After each hazard identification, determine how to mitigate the risk of a safety incident. In the following order of preference, look for ways to:

- Eliminate the hazard: This strategy is the most effective. Potential measures include using a different process, modifying the process or tools, substituting materials, or adapting the work environment (like adding ventilation).

- Contain the hazard: If you can’t eliminate the hazard, controls such as machine guards or work booths may help contain the risk.

- Revise your work procedures: Suggest ways to modify the procedure to lower its risk, like adding or changing steps.

- Reduce job frequency: If you can’t do the above, look for ways to minimize how often employees perform that risky job.

Step 5: Communicate the Findings

All your work to this point is useless if you’re filing your Job Safety Analysis in a binder somewhere. The purpose is to reduce workplace safety hazards, so be sure to:

- Distribute copies of the JSA to all affected employees

- Include safety measures identified in the JSA in employee training programs

- Make the JSA easily accessible to workers with hard copies or within your Environmental Health and Safety Software (EHS).

- Use the JSA to inform refresher training for infrequent jobs

Step 6: Review and Update

A Job Safety Analysis should be a dynamic document that management and employees collaborate on to review and update regularly. Focus on:

- Periodic follow-up: A manager or supervisor should observe the procedure and compare it to the JSA every month.

- After an incident: Part of the incident investigation process should be comparing what happened against JSA procedures. That can help you identify whether you have a gap in the JSA or whether an employee needs additional training.

- Process or equipment changes: Look at the relevant JSA whenever you introduce new equipment or process or revise processes. And be sure your document control is always up to date.

A Job Safety Analysis is only as good as your effort when all is said and done. Just checking the box isn’t likely to produce results. Follow these steps—and build the process into your automated workflows—to be on a more reliable path to safe work.

The Role of EQMS in Enhancing JHA Efficiency

To enhance the effectiveness of your job safety analysis and streamline JHA processes, consider leveraging an electronic quality management system (EQMS). QMS software can streamline the management of workplace hazards and controls. By improving documentation, tracking, and analysis, QMS software ultimately leads to a safer workplace environment.

Incorporating quality management software into your JSA practices further enhances your organization’s commitment to maintaining a safe and productive work environment. Key features of EQMS software for hazard analysis include:

- Centralized data management allows for easy hazard analysis and decision-making.

- Automation helps reduce manual labor and the risk of human error in scheduling, data collection, escalation, review and approval, risk assessment, and auditing.

- Risk assessments and audit trails identify potential workplace safety hazards.

- Training management to ensure all staff get the required training.

- Communication and collaboration workflows ensure staff, safety professionals, and management have real-time updates and notifications.

- Data analysis and reporting help identify trends, prioritize hazards, and track the effectiveness of control measures.

The Impact of Regulatory Compliance on JHA and EQMS

The most important feature of EQMS software is the ability to facilitate compliance with specific regulatory requirements. Many organizations have set safety regulations and security requirements, and failure to comply can lead to fines, penalties, damage to your reputation, and employee turnover. JHA or JSA processes are significantly influenced by this need to comply.

Implementing JHA with your EHS software can create a safer, healthier workplace and help you remain compliant with regulatory guidelines set out by regulatory bodies. JHA can also be used as evidence to prove that staff followed all required safety measures. It can also mitigate severe consequences and streamline your ISO or OSHA compliance processes through your EQMS.

Best Practices for Implementing JHA and EQMS in Your Workplace

JHA processes and your EQMS solution are incredibly important for compliance, workplace safety, and efficiency. However, you must also effectively implement and onboard these tools into your daily operations.

Here are four key best practices for JHA and EQMS implementation in your workplace:

- Stress the need for comprehensive training programs and clear communication of JHA and EQMS objectives to all staff members.

- Emphasize the significance of involving employees in the JHA process and adopting a culture of continuous improvement.

- Highlight the integration of EQMS with existing systems and ensure the accessibility of JHA documents to all employees.

- Point out the necessity of consistent monitoring and enforcement of safety procedures and the advantage of leveraging technology for enhanced efficiency.

Integrating JHA and EQMS for Optimal Safety

JHA, or the analysis of job hazards, is vital for ensuring occupational safety. By following the six steps outlined above, you can conduct JHAs and incorporate learnings into your organizational processes and training.

For effective job safety analysis, integrate your JHA process with an EQMS, like ETQ Reliance. Learn more and contact us today.