Download a copy of “The Pulse of Quality in Manufacturing 2024”

In early 2024, ETQ surveyed 750 senior-level quality professionals across the U.S., U.K. and Germany who were asked about their views on quality in the workplace. The goal was to collect real-world feedback on the trends, issues and challenges that affect quality professionals in those markets. Responses provided valuable insights into the current state of quality management and came from several industries, including heavy industry, electronics, medical devices, pharmaceuticals, food and beverage, chemicals, logistics, automotive and aerospace.

The Growing Concern of Supplier Quality

Maintaining high quality is crucial for success in today’s competitive landscape. However, recent trends indicate supplier-related quality issues are on the rise, posing significant challenges for manufacturers.

Why Are Recalls Increasing?

Several factors contribute to rising product recalls. As supply chains become more global and complex, the potential for quality issues increases. Manufacturers often rely on multiple suppliers from different regions, each with different quality standards and practices. This makes it challenging to maintain consistent quality across the entire supply chain.

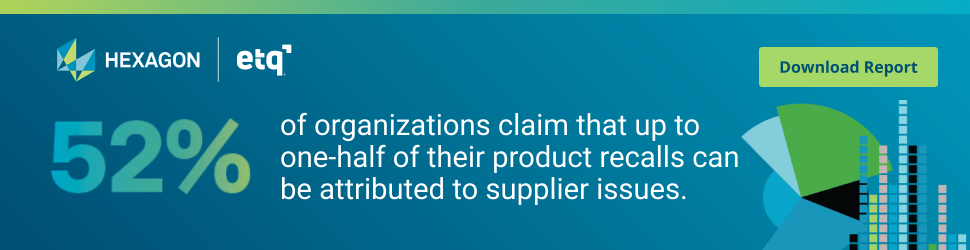

One finding from the survey shows that 62% of those who responded attribute quality issues to suppliers rather than internal processes, and 52% claim that up to one-half of product recalls can be attributed to supplier issues. This highlights the critical role suppliers play in the overall quality of the final product. Although 70% of organizations believe they have control over their suppliers, most product recalls are linked to supplier quality problems.

Regulatory requirements are also becoming more strict, with eight new federal regulations introduced daily, and consumer awareness about product safety at an all-time high. Any deviation from established quality standards can lead to a recall and can result in significant financial and reputational damage.

73% of respondents have experienced a product recall in the last five years, with 48% noting that product recalls have increased in that time, which indicates a growing trend.

This alarming statistic highlights the constant nature of quality issues across manufacturing organizations.

Challenges in Managing Supplier Quality

Managing supplier quality is complex and involves making sure all suppliers follow the same standards as the manufacturing company. However, many organizations struggle with this aspect of quality management for several reasons. Suppliers may have different quality control processes, making it difficult to ensure consistency. Communication and coordination challenges including lack of transparency between suppliers and OEMs, siloed data and slow supplier corrective actions can make these issues worse, leading to the quality failures that result in recalls.

The Consequences of Poor Supplier Quality

Product recalls can lead to significant operational disruptions and extend beyond immediate financial costs. 35% of survey respondents say their brand reputation has been negatively impacted by recalls and supplier issues. A damaged brand reputation can have long-lasting effects, wearing down customer trust and loyalty, making it difficult for the company to recover.

The survey also reveals that 32% of organizations have experienced delayed product introductions due to recalls. Delays in product launches can have a ripple effect, impacting sales targets and market positioning. Additionally, 30% of respondents reported plant shutdowns because of recalls, affecting production schedules and overall efficiency.

26% of respondents said they have had to conduct layoffs as a direct result of recalls and supplier issues. These layoffs not only impact the lives of employees but also lead to a loss of valuable skills and experience within the organization.

Addressing the Challenges

With the increasing incidents of recalls and their impact, manufacturers must take steps to enhance quality management and stay ahead of future problems. One effective strategy is implementing an electronic quality management system (eQMS) like ETQ Reliance®.

An automated, cloud-based eQMS like ETQ Reliance offers a comprehensive solution to the quality challenges faced by manufacturers. By providing real-time visibility into quality processes, an eQMS helps organizations identify and mitigate risks before they result in recalls. It also improves supplier quality management by ensuring that suppliers meet the necessary quality standards.

Conclusion

The data from the survey paints a clear picture: Supplier quality issues pose a significant risk for increased challenges in manufacturing. To ease these issues, manufacturers must closely examine their quality processes and invest in robust quality management systems. Implementing an eQMS like ETQ Reliance can help mitigate risks, improve supplier quality and build a culture of quality. By taking these steps, manufacturers can protect their brand reputation, improve customer loyalty and thrive in a competitive market.

Download a copy of “The Pulse of Quality in Manufacturing 2024”