Tackling the cost of poor quality

The ‘cost of poor quality’ (COPQ) refers to the costs incurred from producing defective products that don’t meet an organization’s minimum quality standards.

The ‘cost of poor quality’ (COPQ) refers to the costs incurred from producing defective products that don’t meet an organization’s minimum quality standards.

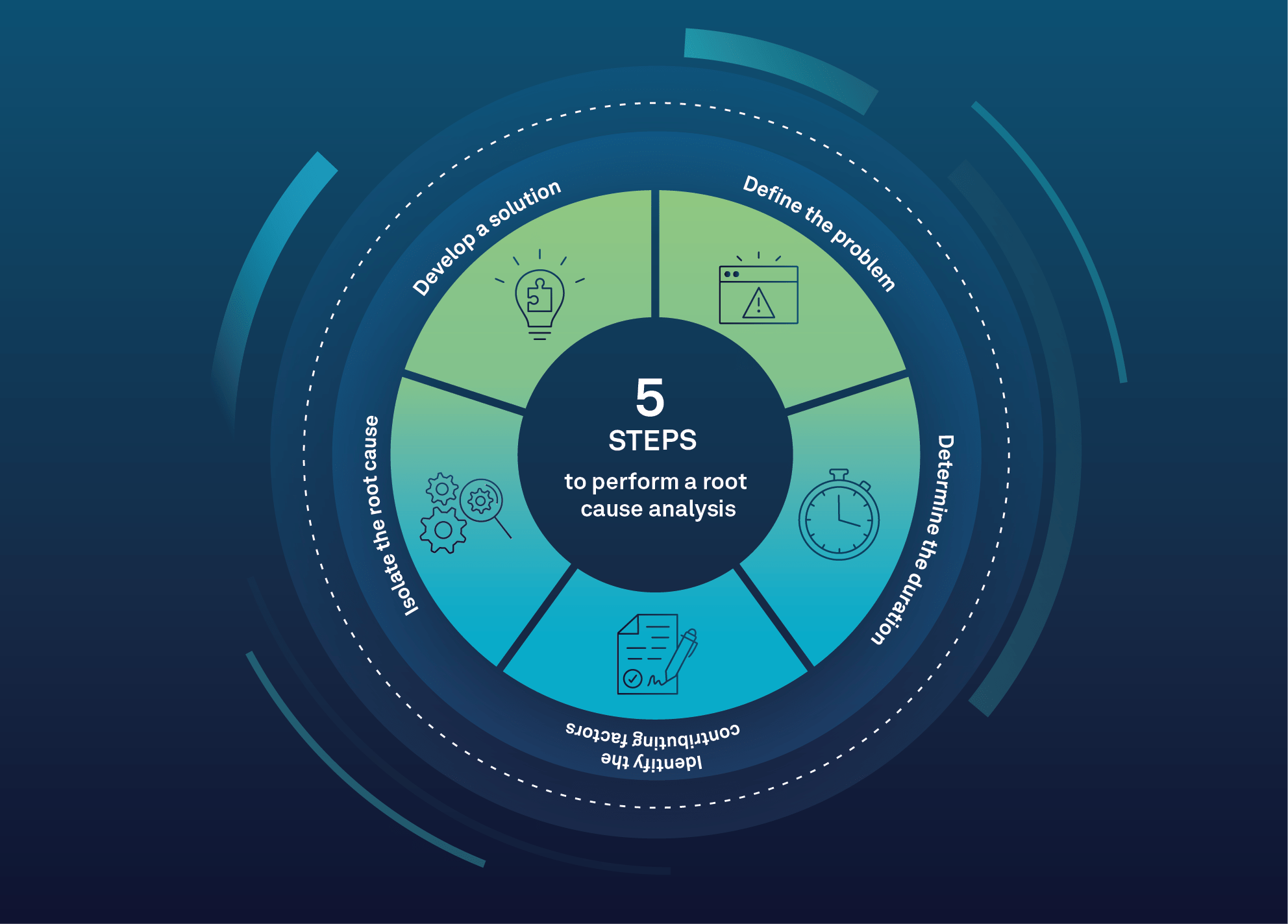

Organizations use root cause analysis (RCA) to find the source of faults or problems in a manufacturing process. Although many factors could contribute to a problem, there’s usually just one forming the root cause.

Many organizations view quality as an unavoidable expense, especially when proactive processes are in place to prevent nonconformance. However, there’s a significant difference between investing in quality upfront and the costly consequences of addressing poor quality after the fact. So, what exactly is the Cost of Poor Quality?

Many organizations might see quality as an expense that is a necessary evil, especially when they have proactive processes in place to avoid nonconformance. But the reality is that there’s a big difference between the costs of good quality and the costs associated with handling and fixing poor quality products. What is the Cost of Poor Quality?

Poor quality comes at a cost—affecting finances, customer trust, and long-term success. Learn how the Cost of Poor Quality (COPQ) impacts businesses.

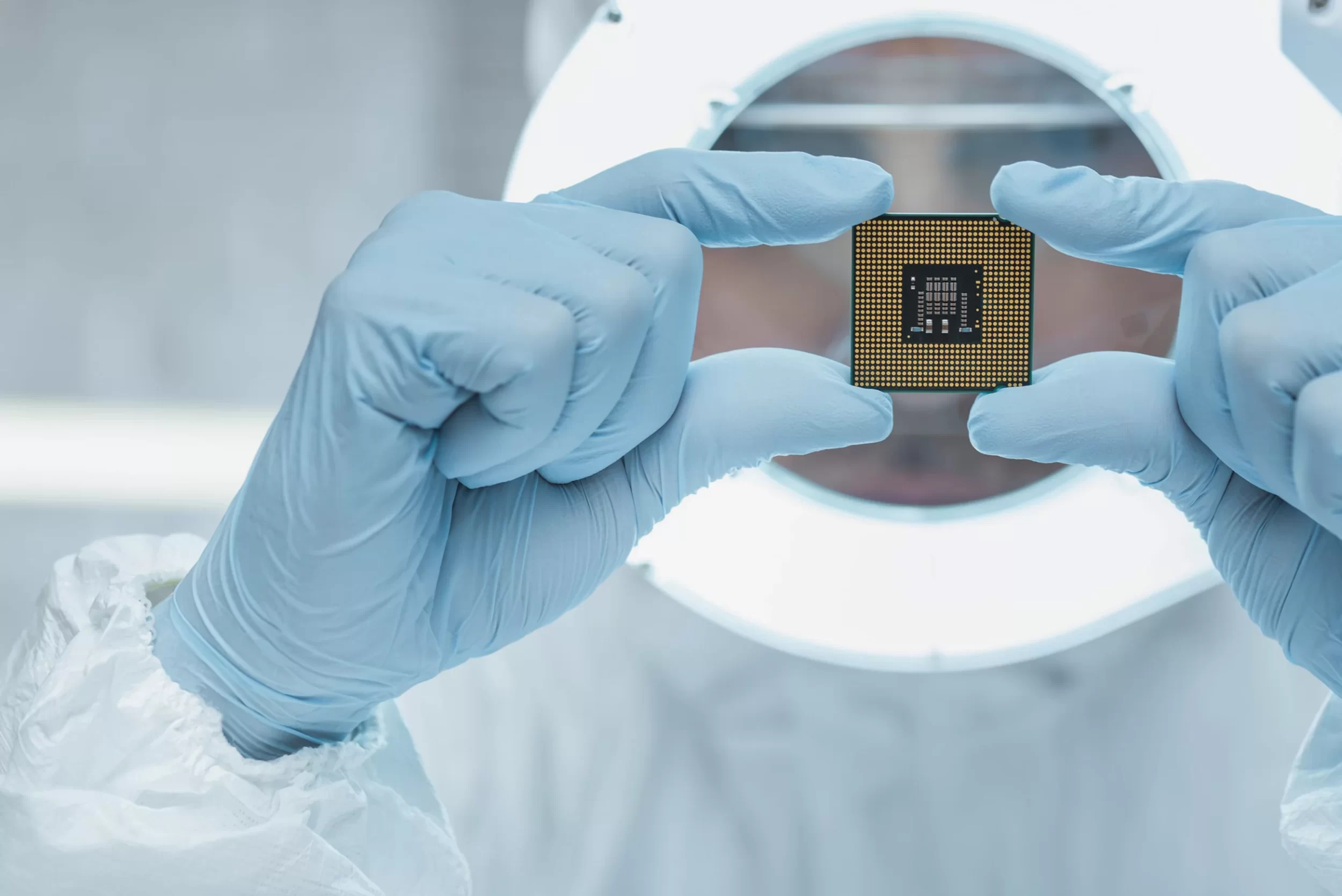

Scaling compliance in biopharma is no small task. As regulations evolve and manufacturing complexities grow, companies need the right solutions to maintain quality, ensure data integrity and streamline processes.

We’re excited to announce that ETQ Reliance® has been recognized with several G2 Badges for Winter 2025, based on reviews from our customers.

Learn how predictive quality analytics transforms manufacturing by using real-time data and AI to predict and prevent issues, optimize processes, and maintain a competitive edge.

Learn how root cause analysis identifies and resolves problems by tracing them to their origin. Discover the steps, tools, and team approaches for effective problem-solving in your organization.

Discover how ISO 9001:2015 strengthened quality management systems, emphasized customer satisfaction, and empowered leadership. Explore 7 essential internal audit checklists to streamline compliance.

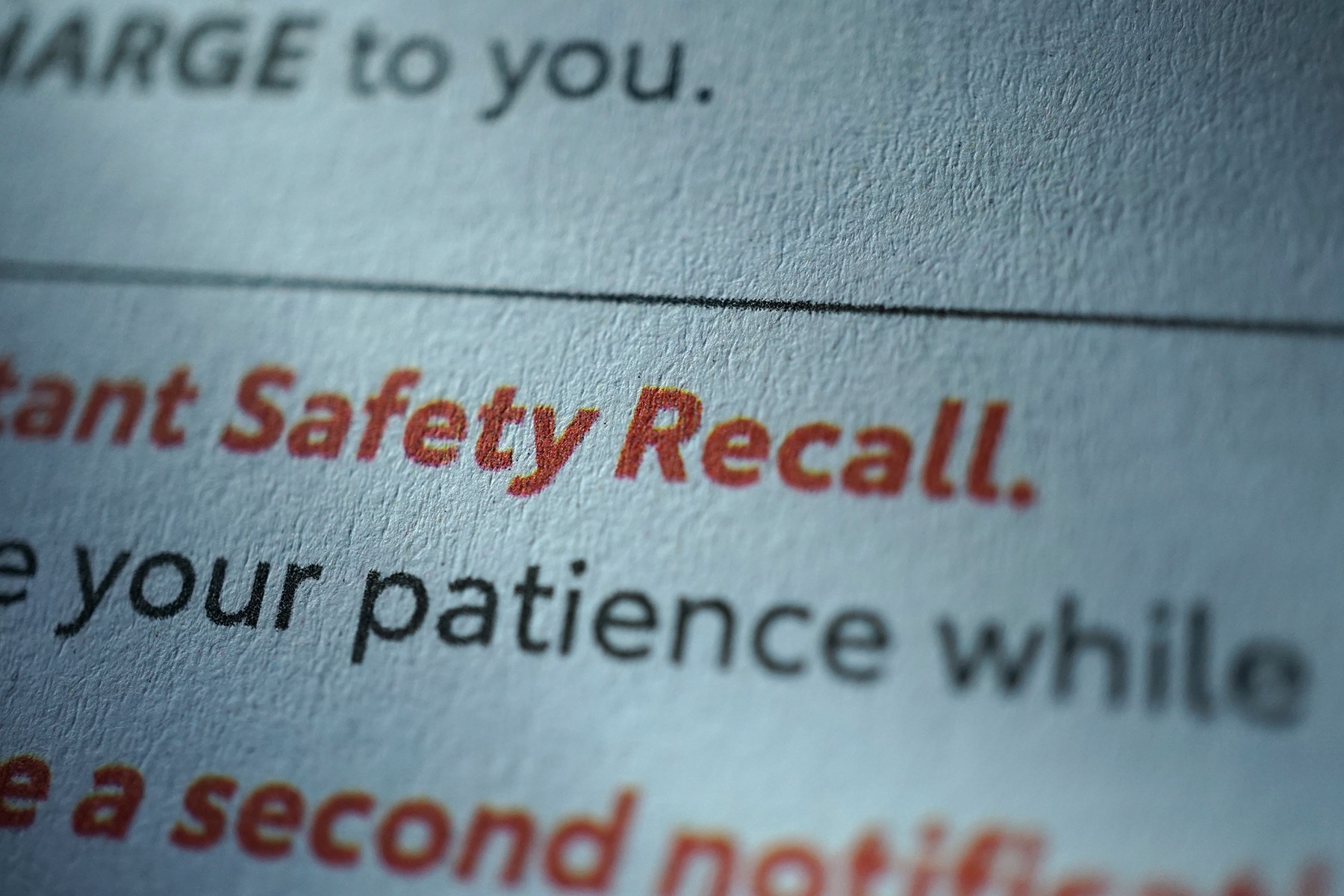

Supply chains become more complex, and regulations become more stringent. This has naturally contributed to a rise in product recalls over the past few years, and these recalls show no signs of slowing down. In fact, according to Sedgwick, recalls in 2024 saw a record high number of product recalls and that trend is expected to continue in 2025.

Learn more

Learn more

Supplier quality control in the food and beverage industry is essential, but companies still face many challenges in ensuring consistent standards

Poor quality control can have ongoing repercussions for food and beverage brands. In addition to the financial impact of recalls, reputational damage which leads to a drop in sales, is also a strong possibility. ETQ polled food and beverage companies in 2024 on their approach to quality and how they cope when things go wrong. In this blog, we dive into the data to uncover the true cost of poor quality, both financial and reputational.

Advances in technology, increased regulatory security and a growing focus on sustainability mean that compliance requirements are becoming stricter across many industries. Protecting brand reputation and preventing costly recalls are driving organizations to make company-wide compliance a top priority.

German manufacturers are facing more product recalls than ever before. Across 750 global organizations surveyed in the recent Pulse of Quality in Manufacturing Report, 48% stated product recalls had increased in the last five years.

Automation plays a key role in improving quality systems in German manufacturing. Already, 86% of German manufacturers use automated quality management systems.

In the world of heavy industry, the cost of poor quality can be monumental. From manufacturing and construction to mining and oil production, companies that operate in these fields face unique challenges in managing quality.

With 60% of electronics companies reporting a product recall in the last five years, it’s clear that even the most advanced technology can find maintaining good quality a challenge.

Quality management in UK manufacturing is undergoing a significant shift driven by automation and AI. Manufacturers in the UK are increasingly recognizing the power of automation to enhance quality management.

UK product recalls are rising and their costs are staggering, though manufacturers can reduce the risk of recalls with AI and supplier oversight.