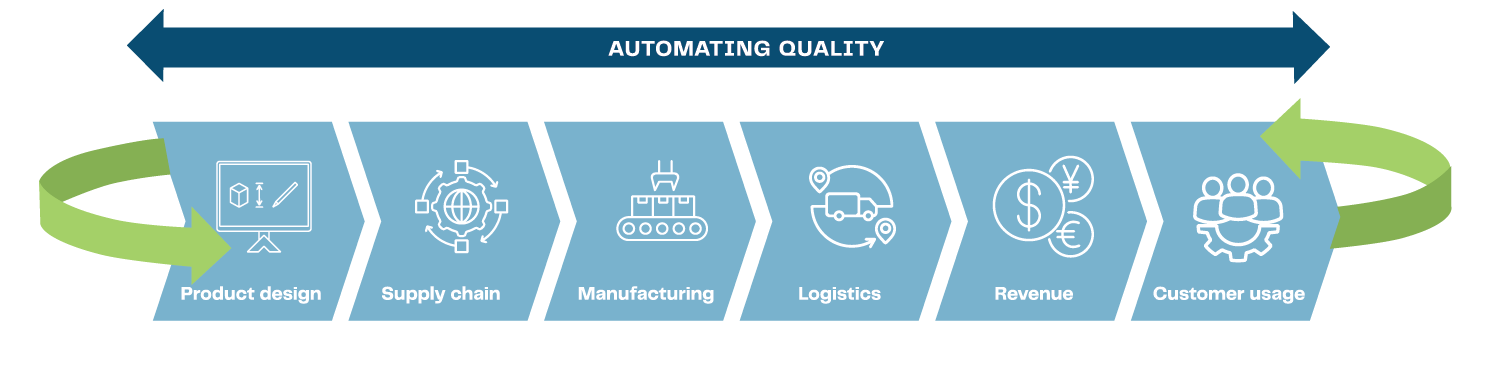

Integration Benefits

The benefits of a closed-loop quality system

- Eliminate manual data entry with digital inspections and worker input

- Detect and resolve issues earlier with predictive quality analytics

- Improve visibility across operations, suppliers and compliance programs

- Empower frontline teams with real-time instructions and guided workflows

- Align QC and QA to accelerate cycle times and reduce the cost of poor quality